Six Stage 80 GPD Unit with Booster Pump

I use a SpectraPure 80 Gallon Per Day RO/DI Unit that has been mounted to the wall in my reef room. This unit has a Pressure gauge to show current PSI level, a flush valve (top of unit - blue valve with yellow tubing) and I replaced the standard Spectrapure Conductivity Monitor with two Dual TDS meters. The unit's has several stages which are:

The black box on top is a solenoid valve that kills the power to the booster pump and turns off the water feed in the event of a power outage. It is also connected to a float switch to kill the power and water supply when the holding vessel is full of water. |

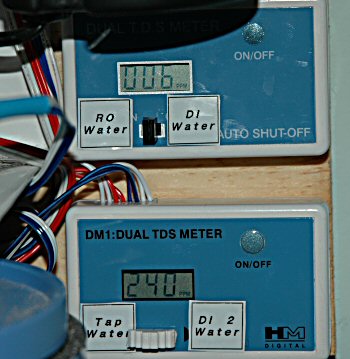

Two Dual TDS Meters

Picture left is a close up of the two Dual TDS meters. TDS is an acronym for Total Dissolved Solids. These units are dual units in that it has two sensors per device. I have a sensor attached to the source water line (Tap Water), a sensor on the output of the RO membrane, a two sensors on the output of the DI cartridge. I just flip a lever to select which sensor to display a reading for. The picture shows the water coming out of the RO membrane at 6 ppm which is excellent which is a little on the high side (my membrane is old). I would rather see a reading around 2 or 3 ppm. I can use the DTS meters to calculate my RO membrane's rejection ratio. You should replace your RO membrane every 2 years or if your membrane rejection rate falls below 98%. My tap water is showing a reading of 240 ppm TDS. The RO membrane is removing 234 ppm TDS (since only 6 ppm is getting past). That is about a 97.5% rejection rate. My RO membrane is about 3 years old and is showing signs it needs to be replaced. I currently have two sensors on the DI cartridge output. A fresh DI cartridge should show 0 ppm TDS. Be ready to replace the cartridge when it reads 1 ppm TDS and I suggest replacing it before 2 ppm TDS is displayed. |

SpectraPure RO Flush Valve Kit

This is a flush valve. It is attached to the waste line of the RO membrane. The primary purpose of the flush valve is to bypass the flow restrictor in the waste line. The flow restrictor is in the curved part of the yellow tube and water is squeezed into the flow restrictor by the house water pressure and booster pump. (The flow restrictor is just a very narrow tube inside the waster line and it's length determines the amount of waste water that will be produced). When opened, the valve bypasses the flow restrictor and allows water to enter the RO membrane at full force and flush out many of the impurities that have built up in the membrane. I open the valve for about 2 minutes before and after I make water. |

SpectraPure 80GPD RO Membrane

This is a what a new RO membrane looks like. All membranes look like this, some are thicker than others depending on the gallons per day rating. |

SpectraPure RO Booster Pump

To the left you can see the SpectraPure water booster pump I use to raise my water pressure to the RO unit to about 85 to 95 PSI. If a float switch is used then I set the booster pump to 70 PSI which is the maximum rated pressure for my switch. |

Tamco 55 Gallon Water Change Tank

This is a 55 gallon water tank I use for making water changes. The tank is made by Tamco and is FDA approved for food use. It is made from medium density polyethylene and is UV stabilized. The container already had the graduated marks. I highlighted them with a red marker to make it easier to read. You can get an idea of how large it is by the salt buckets next to it. The Instant Ocean buckets behind it are 200 gallon salt mixes buckets. The following link is an article on how I previously processed tap water with deep well issues. |